Drilling an ultra-precise hole can be tough. Material behavior, surface irregularities, and drill point geometry can all be factors leading to inaccurate holes.

A Spot Drill, if used properly, will eliminate the chance of drill walking and will help to ensure a more accurate final product.

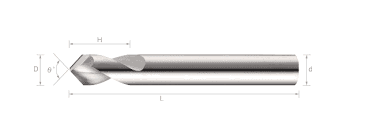

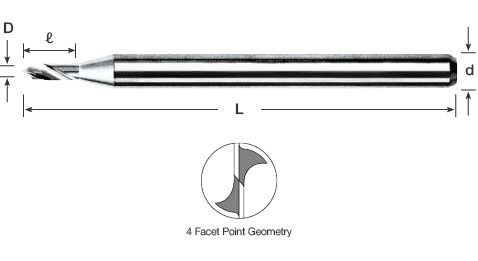

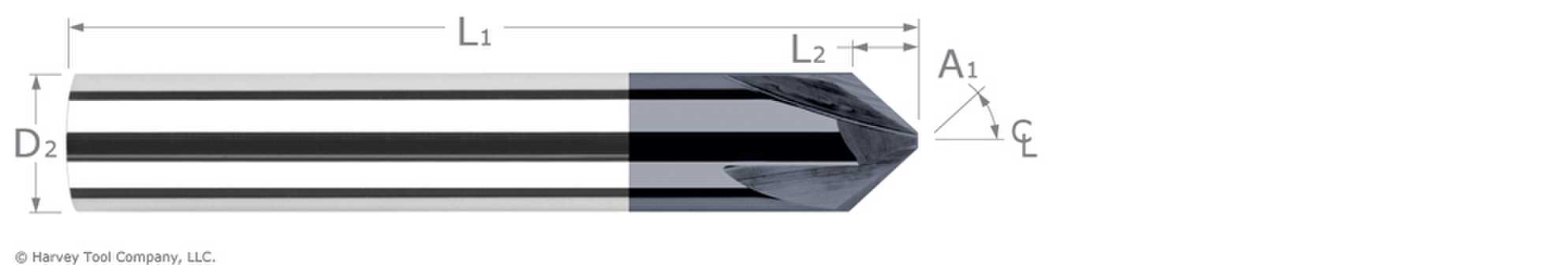

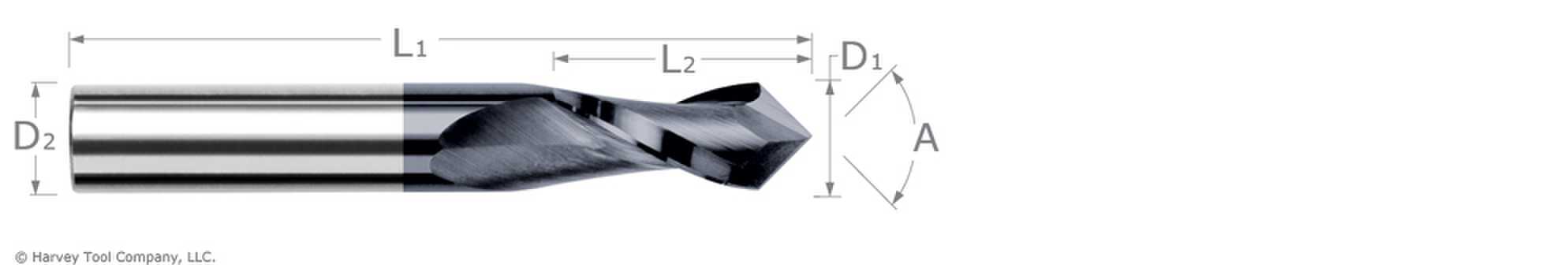

Carbide Spot Drill should always be the first point to contact your part. Therefore, a spotting drill should have a slightly larger point angle than that of your drill. If a spotting drill with a smaller point angle than your drill is used, your drill may be damaged due to shock loading when the outer portion of its cutting surface contacts the work piece before the center. Using a drill angle equal to the drill angle is also an acceptable situation.

Carbide Spot Drill 82º 90º 100º 120º( Uncoated )

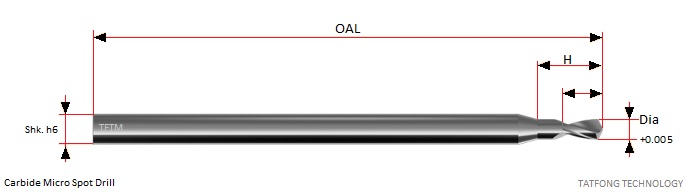

| ORDER CODE | Dia (mm) | CL | Shk | OAL |

| CSD01090 | 1.0mm | 3 | 4 | 50 |

| CSD02090 | 2.0mm | 3 | 4 | 50 |

| CSD03090 | 3.0mm | 4.5 | 3 | 50 |

| CSD04090 | 4.0mm | 6 | 4 | 50 |

| CSD05090 | 5.0mm | 6 | 5 | 50 |

| CSD06090 | 6.0mm | 9 | 6 | 50 |

| CSD08090 | 8.0mm | 11 | 8 | 60 |

| CSD10090 | 10mm | 13 | 10 | 75 |

| CSD12090 | 12mm | 16 | 12 | 75 |

| CSDL03090 | 3.0mm | 4.5 | 3 | 75 |

| CSDL04090 | 4.0mm | 6 | 4 | 75 |

| CSDL05090 | 5.0mm | 6 | 5 | 100 |

| CSDL06090 | 6.0mm | 9 | 6 | 100 |

| CSDL08090 | 8.0mm | 11 | 8 | 100 |

| CSDL10090 | 10mm | 13 | 10 | 100 |

| CSDL12090 | 12mm | 16 | 12 | 100 |

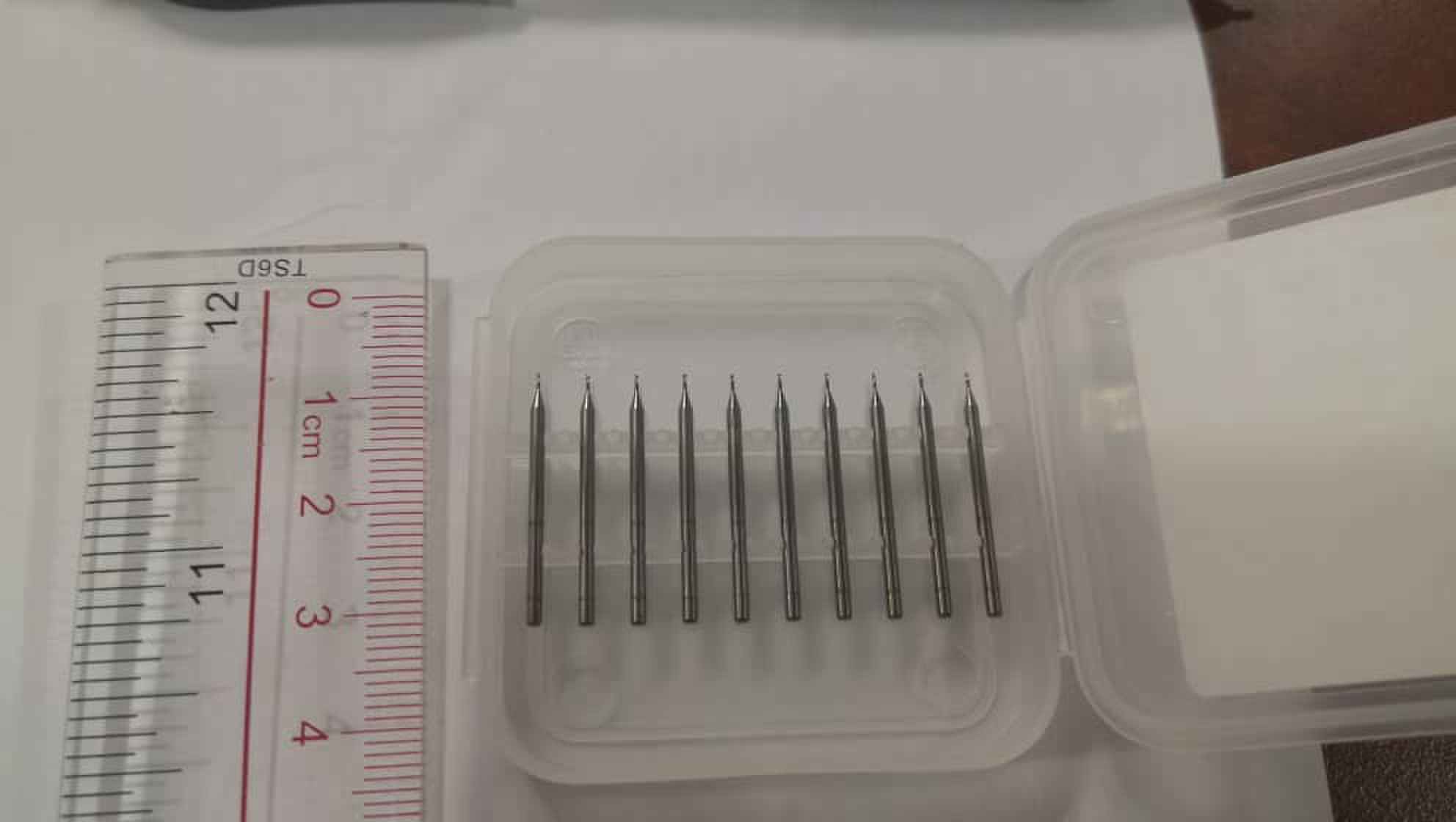

| CSD003130S | 0.3mm | 0.6 | 1.5 | 25 |

| CSD004130S | 0.4mm | 0.4 | 1.5 | 25 |

| CSD005130S | 0.5mm | 1.0 | 1.5 | 25 |